Catalogue

Home- Catalogue

- American Standard

- British Standard

- German Standard

- Bs En 1092-1:2002

- Fasteners

- Gaskets

- Class 150 Flanges

- Class 300 Flanges

- Class 600 Flanges

- Class 900 Flanges

- Class 1500 Flanges

- Class 2500 Flanges

- Weldneck Flanges & Weights

- Tolarence of Flanges

American Standard » Class 900 Flanges

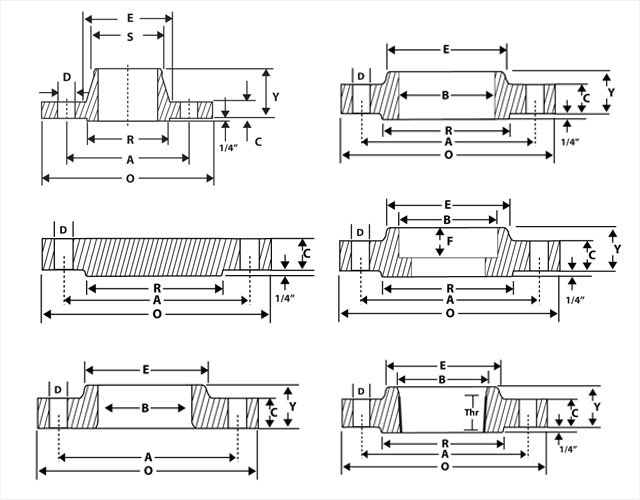

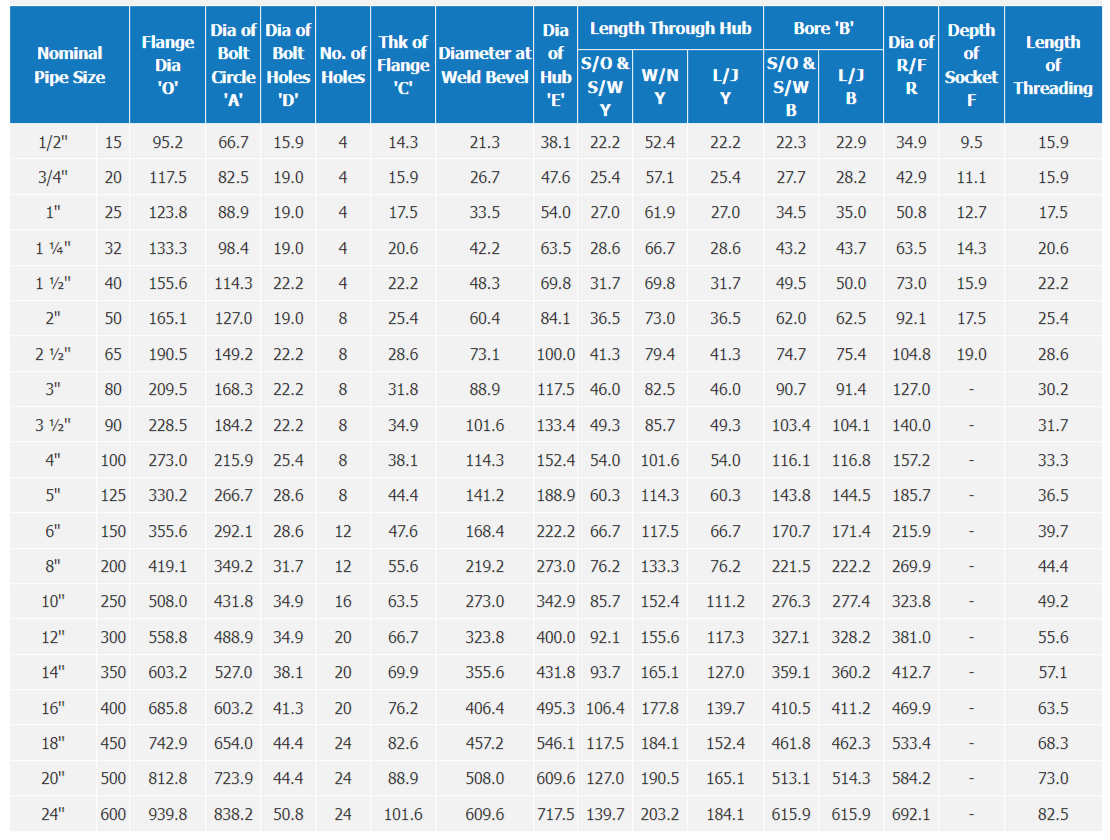

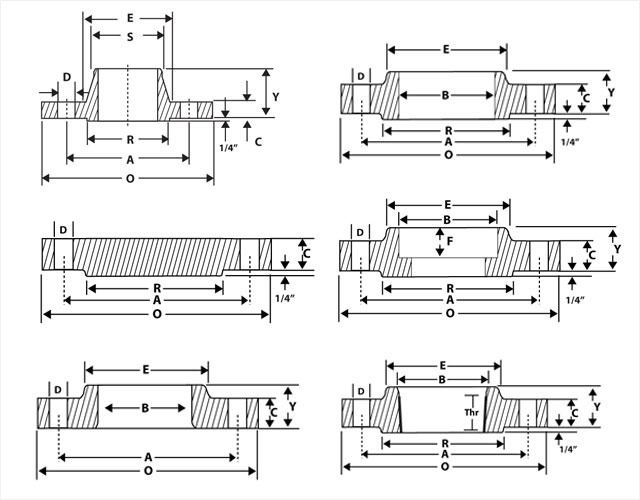

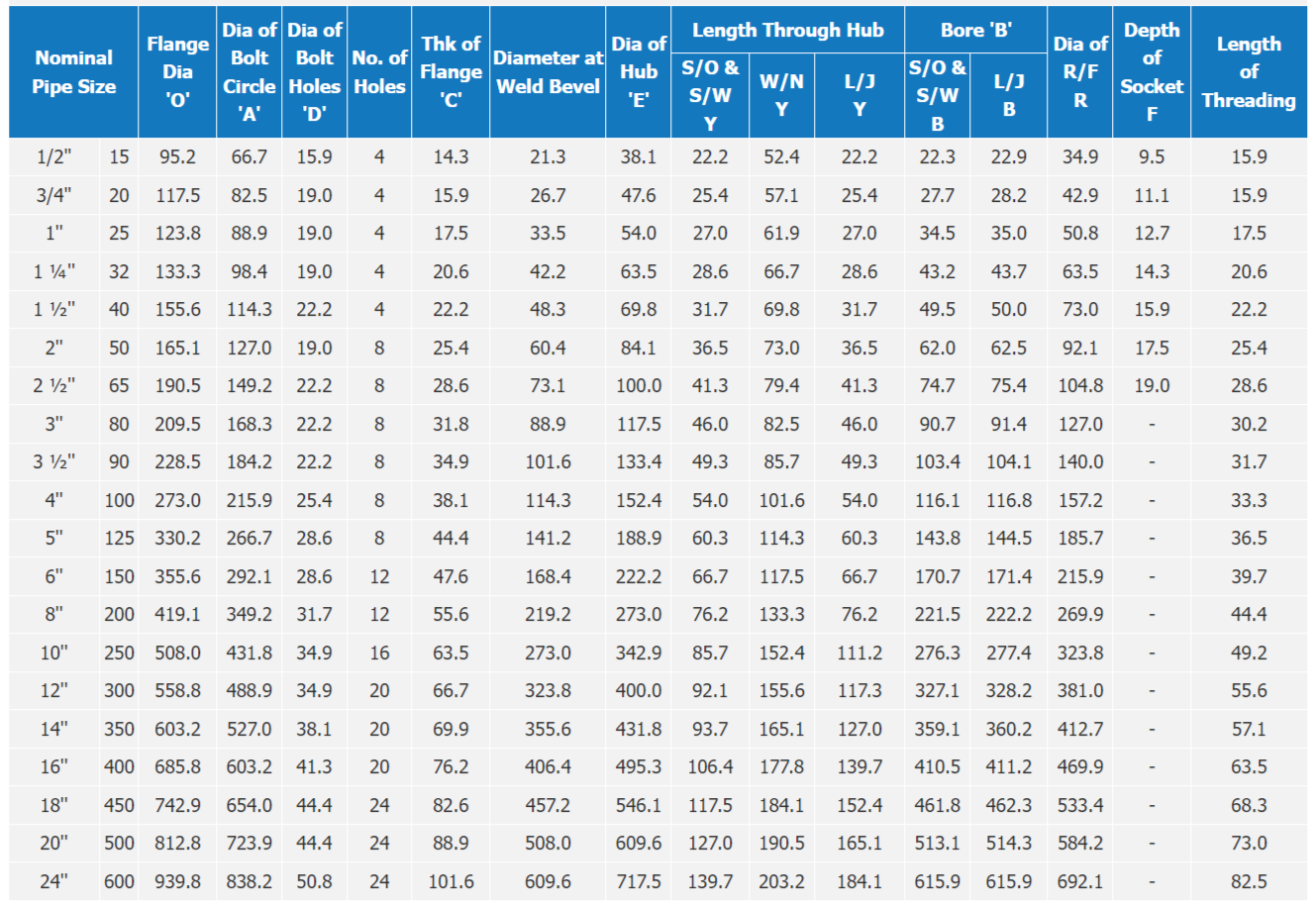

DIMENSIONS OF CLASS 900 FLANGES (ANSI B 16.5) (in mm)

Note: Thickness ‘C’ is exclusive of Raised Face Thickness of 6.25 MM. For Class 900

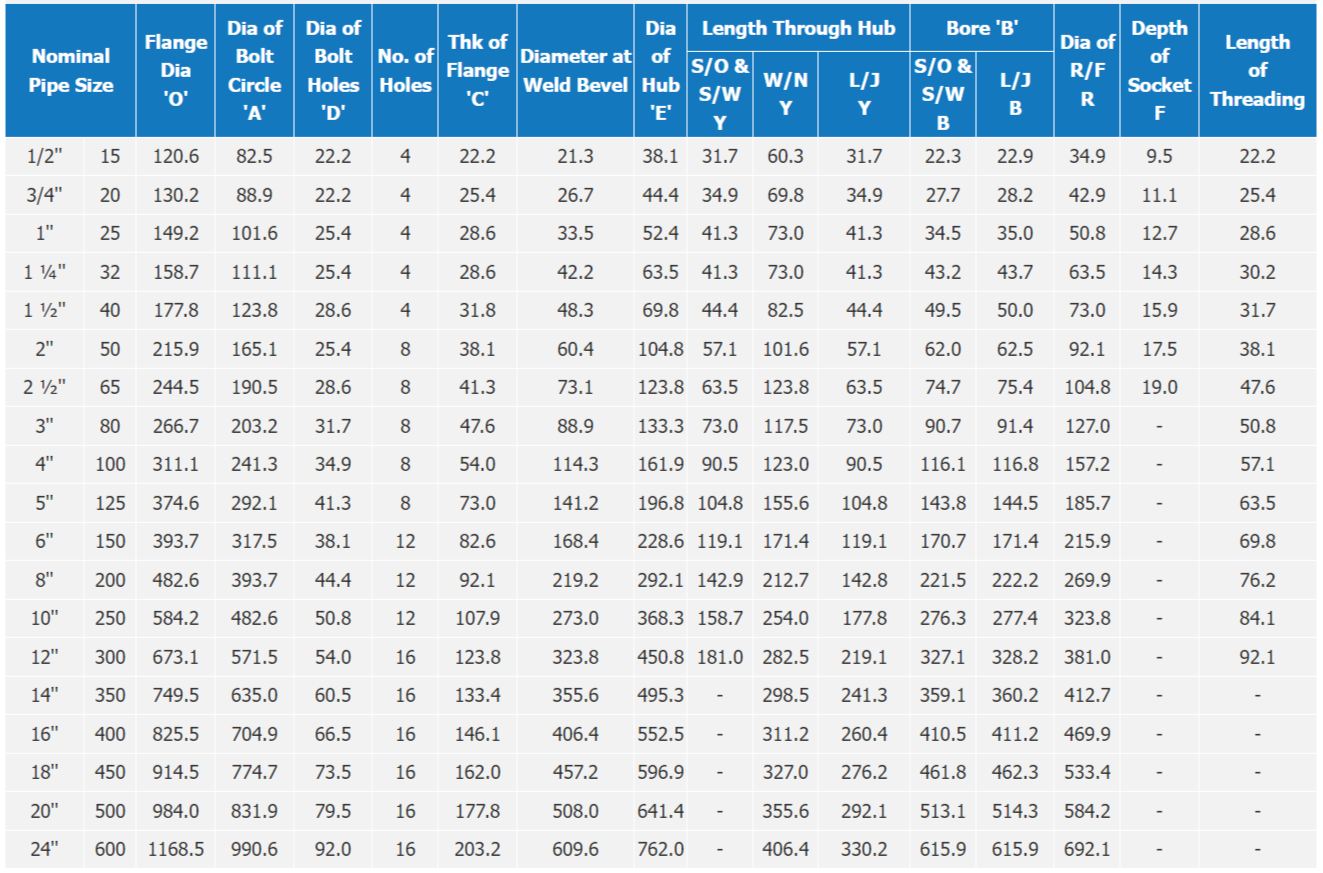

American Standard » Class 300 Flanges

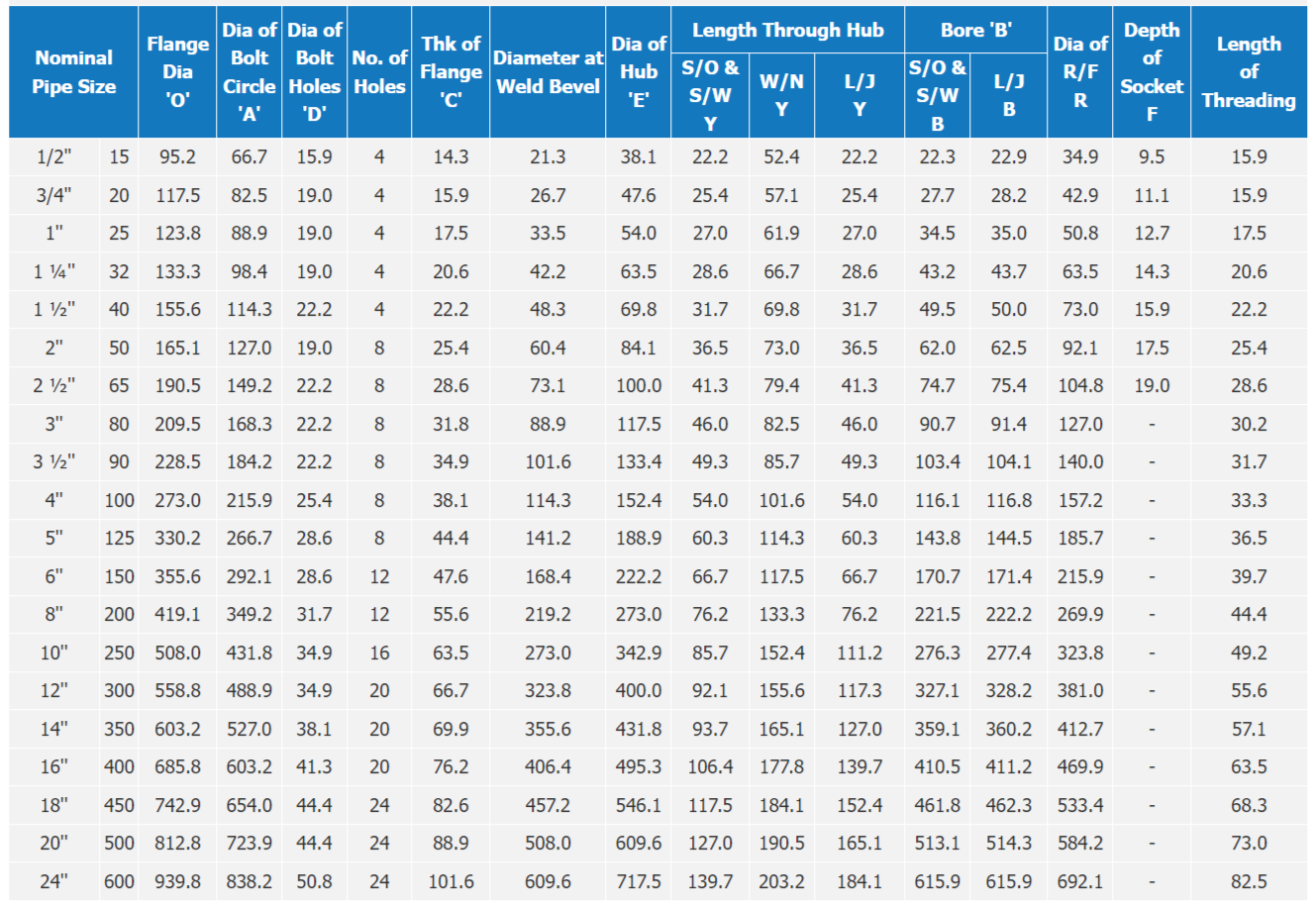

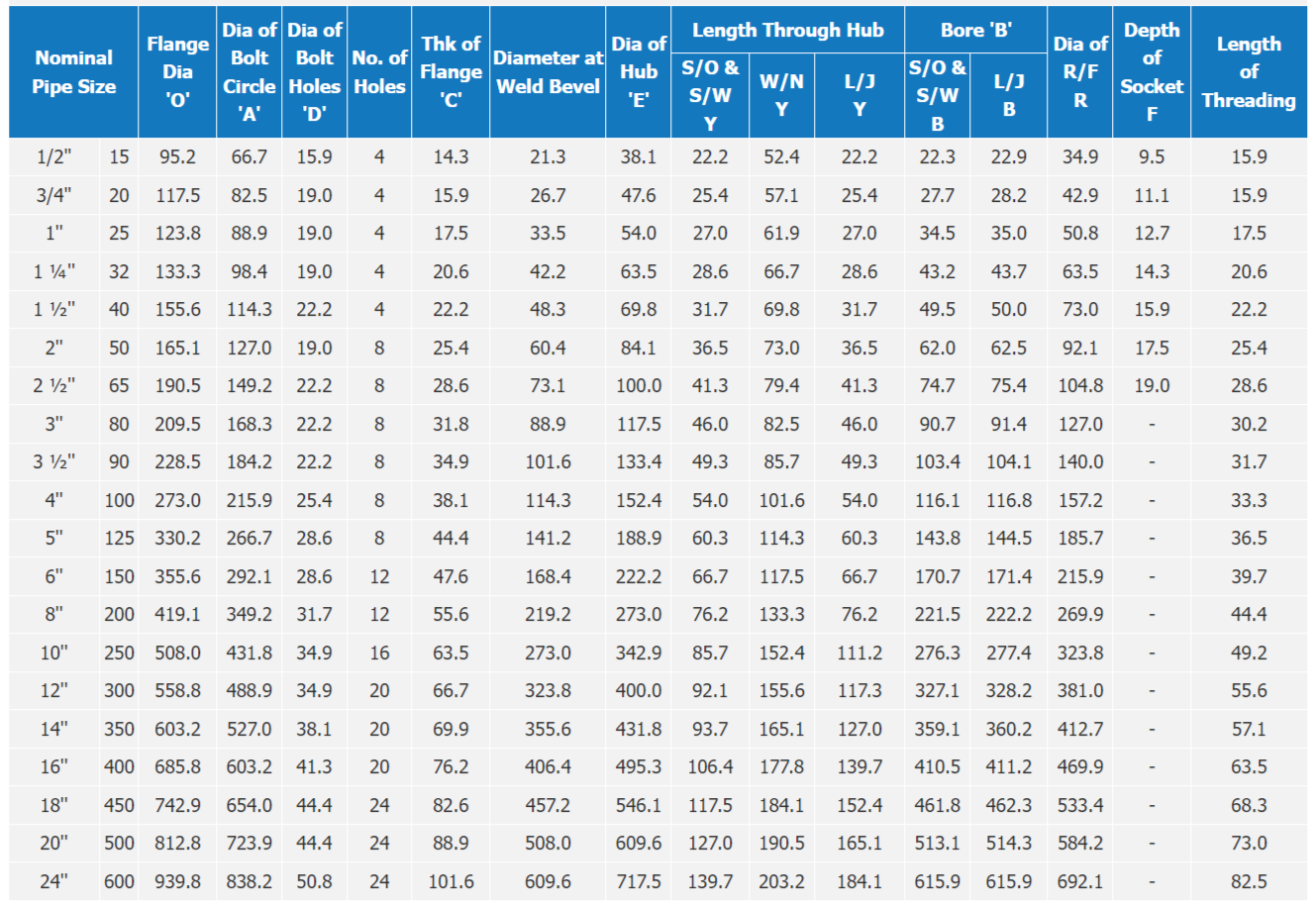

DIMENSIONS OF CLASS 300 FLANGES (ANSI B 16.5) (in mm)

Note: Thickness ‘C’ is inclusive of Raised Face Thickness of 1.65 MM. For Class 300

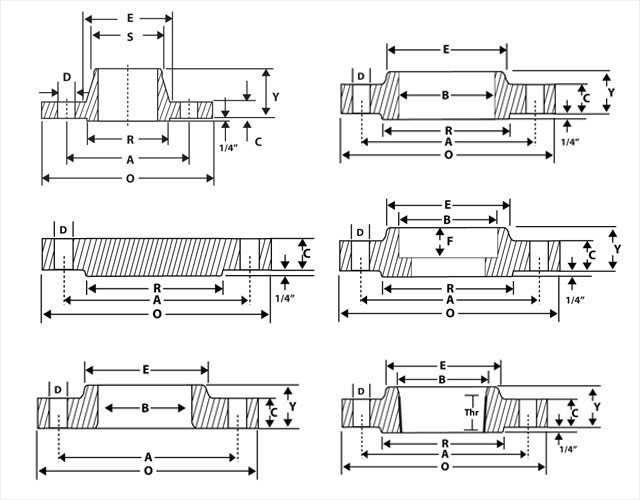

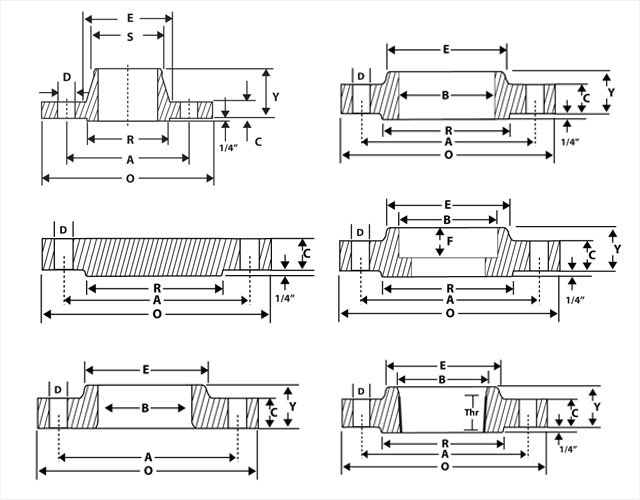

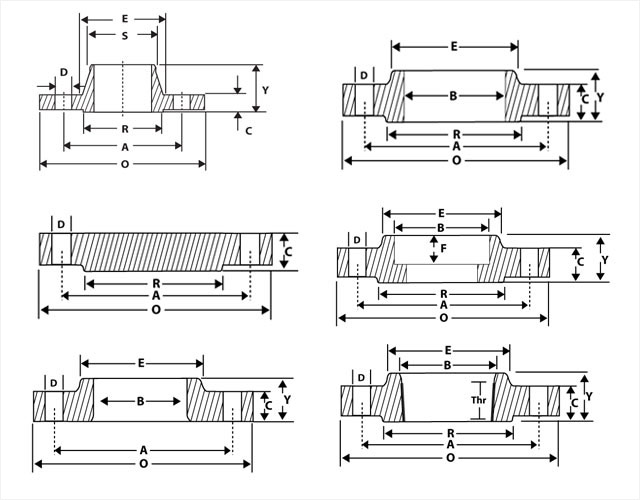

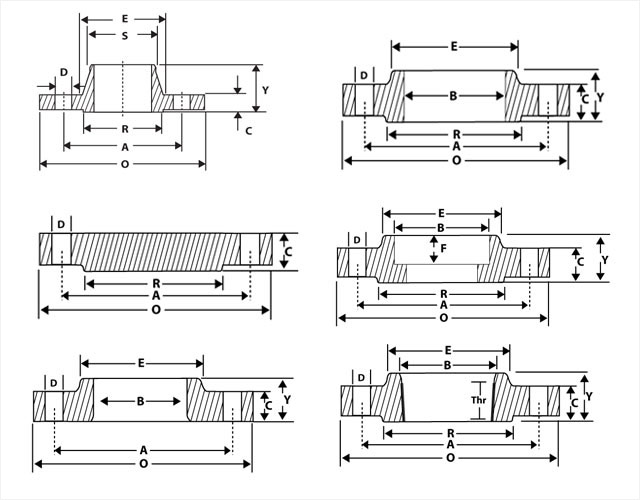

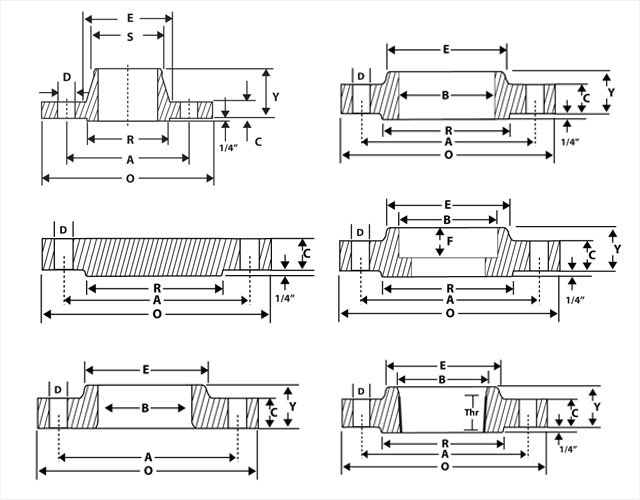

• Welding Neck Flanges

• Slip on Flanges

• Blind Flanges

• Threaded Flanges

• Lap Joint Flanges

• Socket Weld Flanges

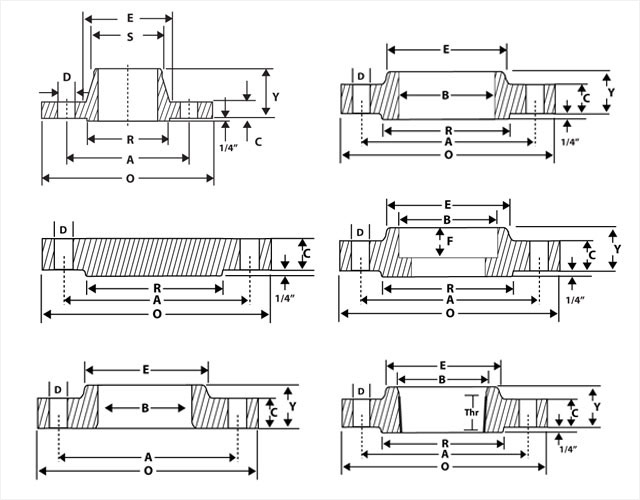

American Standard » Class 600 Flanges

DIMENSIONS OF CLASS 600 FLANGES (ANSI B 16.5) (in mm)

Note : Thickness ‘C’ is exclusive of Raised Face Thickness of 6.25 MM. For Class 600

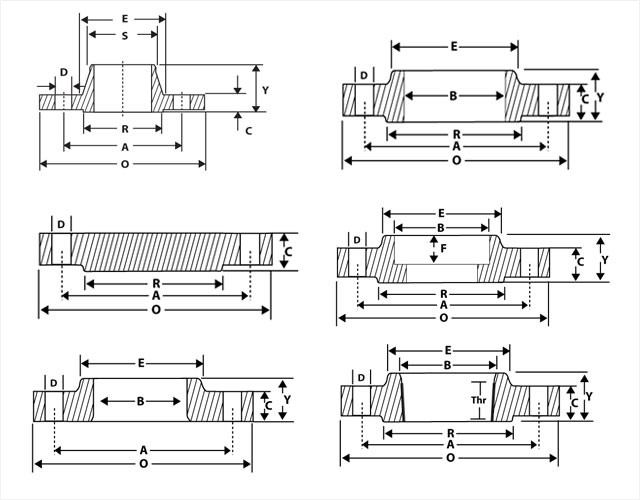

American Standard » Class 900 Flanges

DIMENSIONS OF CLASS 900 FLANGES (ANSI B 16.5) (in mm)

Note: Thickness ‘C’ is exclusive of Raised Face Thickness of 6.25 MM. For Class 900

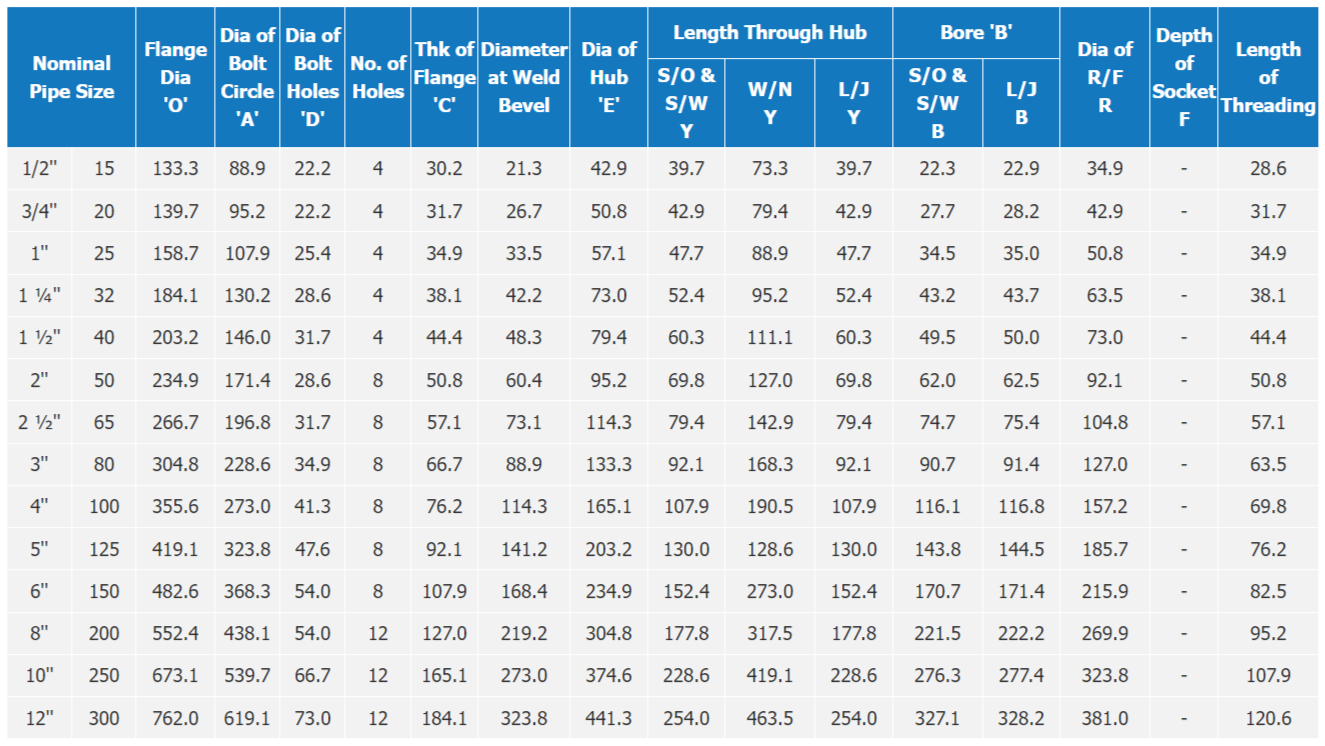

American Standard » Class 1500 Flanges

DIMENSIONS OF CLASS 1500 FLANGES (ANSI B 16.5) (in mm)

Note: Thickness ‘C’ is exclusive of Raised Face Thickness of 6.25 MM. For Class 900

DIMENSIONS OF CLASS 2500 FLANGES (ANSI B 16.5) (in mm)

DIMENSIONS OF CLASS 2500 FLANGES (ANSI B 16.5) (in mm)

Note: Thickness ‘C’ is exclusive of Raised Face Thickness of 6.25 MM. For Class 2500

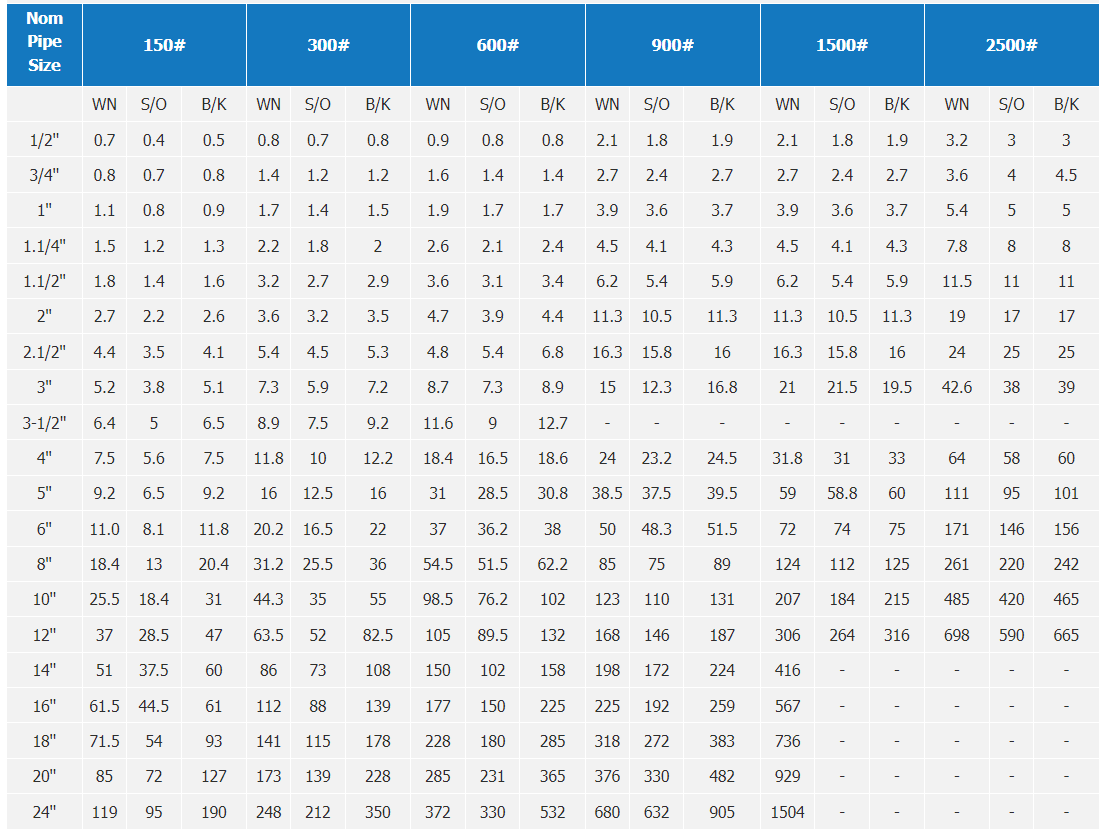

American Standard » Schedule of Weldneck Flanges & Weights

ANSI FLANGES WEIGHT (KGS)

Weldneck flanges

Weldneck flanges have drilled wall thickness which is of equally same dimension existing for matching pipe. Bore will be larger if the pipe is lighter and opposite will be true if pipe is heavier and the bore will be small.

Erosion as well as turbulence is significantly reduced in pipeline as bores of flange & pipe match. Due to these reasons weldneck flanges are chosen for critical applications where high pressure and hot-cold temperatures are prevalent. The different kinds of weldneck flanges available are:

• Weld neck flanges – raised face

• Weld neck flanges – flat face

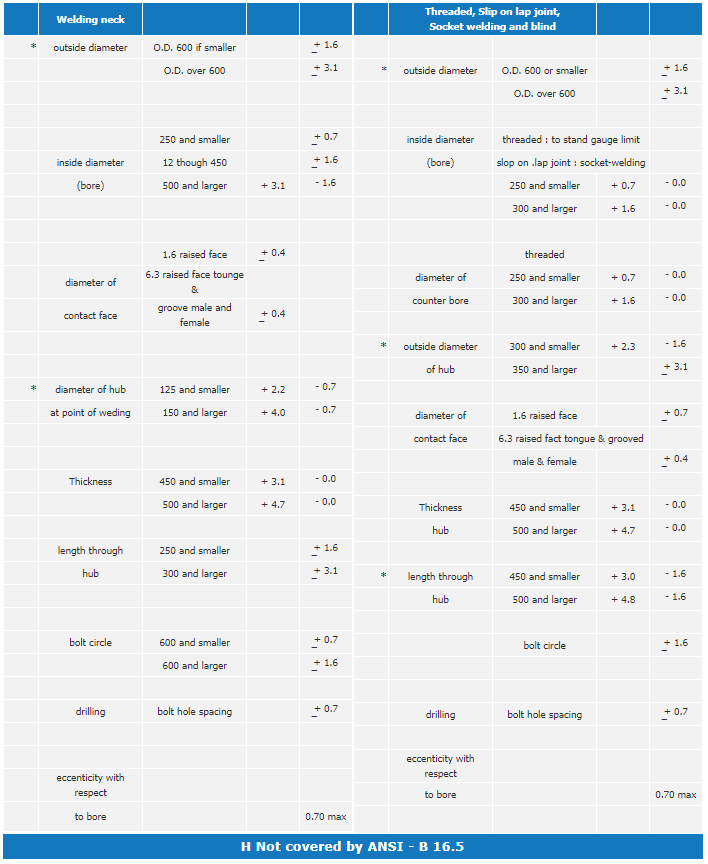

American Standard » Tolarence of Flanges

DIMENSIONS TOLERANCES OF FLANGES (in mm)

H Not covered by ANSI – B 16.5

- Class 150 Flanges

- Class 300 Flanges

- Class 600 Flanges

- Class 900 Flanges

- Class 1500 Flanges

- Class 2500 Flanges

- Weldneck Flanges & Weights

- Tolarence of Flanges

American Standard » Class 900 Flanges

DIMENSIONS OF CLASS 900 FLANGES (ANSI B 16.5) (in mm)

Note: Thickness ‘C’ is exclusive of Raised Face Thickness of 6.25 MM. For Class 900

>>Man Power

Leverage diverse talents and skills to achieve collective goals efficiently.

- The team comprises of two qualified and experienced Engineers with a four member team equally experienced to complement them.

- All our operators follow quality standards and are industry certified.

- We also have about ten skilled labor to take care of post production formalities.

>> Machinery

Utilize state-of-the-art machinery to streamline operations and enhance productivity.

- The Machine shop consist of lathes , drilling machines, necessary jigs , fixtures and inspection instruments.

- Equally well equipped is the Fabrication Shop.

- A k – 400 MIG Welding set, Rectifier and Generator , an electrodes over (300° C) and all other necessary tools and tackles required for fabrication.

>> Recent Works

Forward Momentum: Recent Endeavors Unveiled

- Manufactured 1800 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 1600 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 800 & 900 NB weld neck 300 class Flanges for S.K ENTERPRISES. under third party inspection of bureau veritas.

- Manufactured special o.d & i.d 200 NB & 150 NB Flanges for MC.NALLY BHARAT ENG. PVT LTD. under third party inspection of bureau veritas.

>> Recent Works

Forward Momentum: Recent Endeavors Unveiled

- Manufactured 1800 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 1600 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 800 & 900 NB weld neck 300 class Flanges for S.K ENTERPRISES. under third party inspection of bureau veritas.

- Manufactured special o.d & i.d 200 NB & 150 NB Flanges for MC.NALLY BHARAT ENG. PVT LTD. under third party inspection of bureau veritas.

>> Recent Works

Forward Momentum: Recent Endeavors Unveiled

- Manufactured 1800 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 1600 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 800 & 900 NB weld neck 300 class Flanges for S.K ENTERPRISES. under third party inspection of bureau veritas.

- Manufactured special o.d & i.d 200 NB & 150 NB Flanges for MC.NALLY BHARAT ENG. PVT LTD. under third party inspection of bureau veritas.

>> Recent Works

Forward Momentum: Recent Endeavors Unveiled

- Manufactured 1800 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 1600 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 800 & 900 NB weld neck 300 class Flanges for S.K ENTERPRISES. under third party inspection of bureau veritas.

- Manufactured special o.d & i.d 200 NB & 150 NB Flanges for MC.NALLY BHARAT ENG. PVT LTD. under third party inspection of bureau veritas.

>> Recent Works

Forward Momentum: Recent Endeavors Unveiled

- Manufactured 1800 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 1600 NB Flanges for M/S HYDRASUN (INDIA) under third party inspection of bureau veritas.

- Manufactured 800 & 900 NB weld neck 300 class Flanges for S.K ENTERPRISES. under third party inspection of bureau veritas.

- Manufactured special o.d & i.d 200 NB & 150 NB Flanges for MC.NALLY BHARAT ENG. PVT LTD. under third party inspection of bureau veritas.

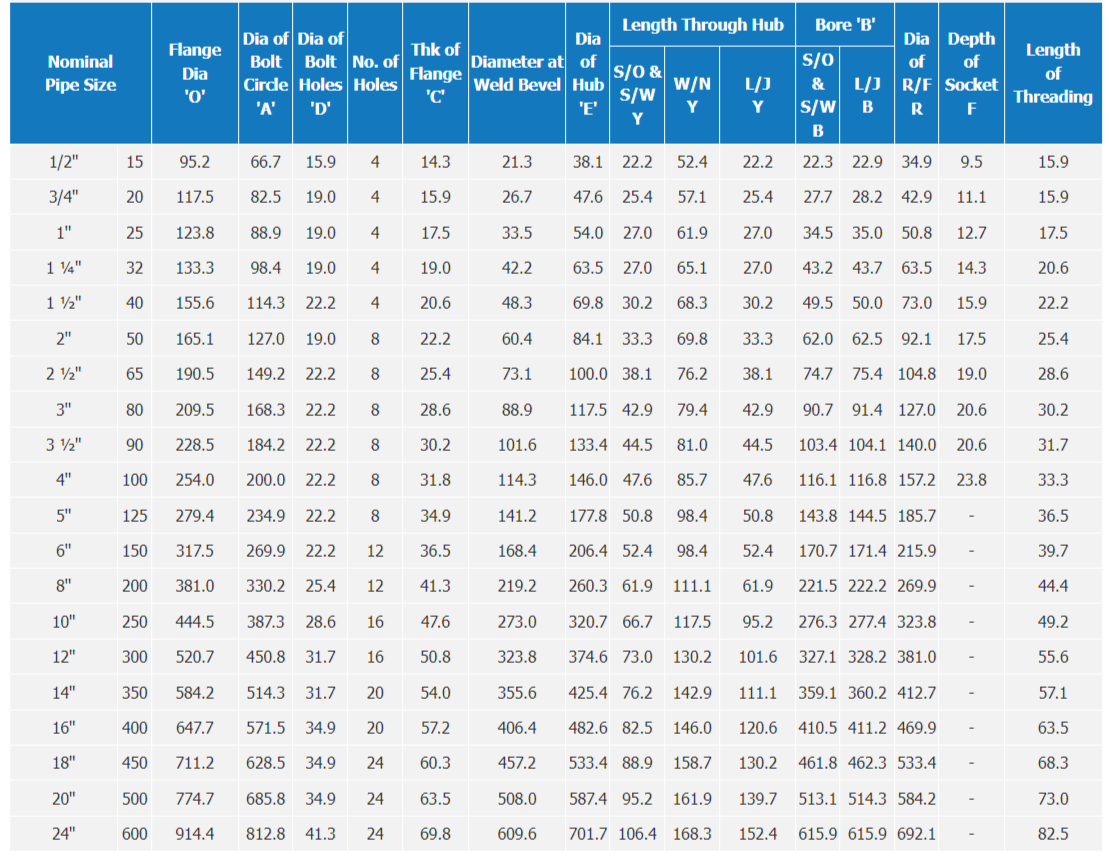

American Standard » Class 2500 Flanges

DIMENSIONS OF CLASS 2500 FLANGES (ANSI B 16.5) (in mm)

Note : Thickness 'C' is inclusive of Raised Face Thickness of 1.65 MM. For Class 150

A class 150 flange can be created from various materials like stainless steel, carbon steel, ductile iron, cast iron, etc and is resistant to abrasion & corrosion with high durability. Flanges such as American standard flanges, British standard flanges and German standard flanges created using above mentioned materials have separate pressure ratings.

The pressure rating of flanges depends on various factors which we will look at in the following section.

Flanges are able to resist different pressure values at different & varied temperatures. With increase in temperature pressure rating of a flange decreases. Let us take an example to illustrate what happens; Class 150 flanges rates to about 270 PSIG (in ambient conditions), at 400 F a PSIG of 180, at 600 F a PSIG of 150 & 75 PSIG at 800 F. So it all depends on the fluid’s operating temperature.

Different types of Class 150 Flanges:

• Welding neck flanges

• Slip on flanges

• Blind flanges

• Threaded flanges

• Lap joint flanges

• Socket weld flanges

Our Creed

Our Creed is rooted in our unwavering dedication to excellence. It serves as our guiding principle, shaping every decision and action we take. With integrity as our cornerstone, we strive to exceed expectations and deliver exceptional results. Fueled by innovation and a commitment to continuous improvement, we embrace challenges as opportunities for growth. Our Creed inspires us to make a lasting impact, driving positive change within our organization and beyond.

We believe in:

- Continuously improving Quality, Processes and Customer Service.

- Eliminating delays, errors and effects in materials and workmanship.

- Providing customers with access to statistical evidence that quality is incorporated in our products and production processes.

- Requiring suppliers to provide statistical evidence of quality in products and process capabilities.

- Sharing with the organization the cost of poor quality in products and services.

- Driving out fear and bringing problems to light for all to see.

- Working together to address specific problems and establish goals and solutions as a team.

- Controlling manufacturing processes which determine the final cost and quality of our products.

- Removing barriers which stand between employees and their pride of workmanship, and implementing ongoing training, supervision and employee development programs.

- Good housekeeping, which reflects on the company, its operating philosophy and our people.

- Encouraging a corporate culture which will reinforce the objectives of our mission on a day-to-day basis.